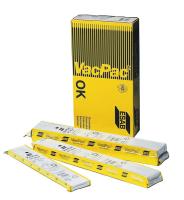

Welding and Gas

Ahlsell's range of tools and machines includes power tools, hand tools, plumbing tools, hand, torch and flashlights, measuring and marking tools, cutters, grinding and brushes, brushes, rollers, wallpaper, and painting tools, cutting tools, welding and gas, compressed air, hydraulics, pneumatics, rubber cloths and vibration damping, cleaning tools, property and office, tools and garden products. We value reliable products that last a long time. That is why you will find tools and machines of high quality in our range. Explore all our tools and machines online or in one of our stores.